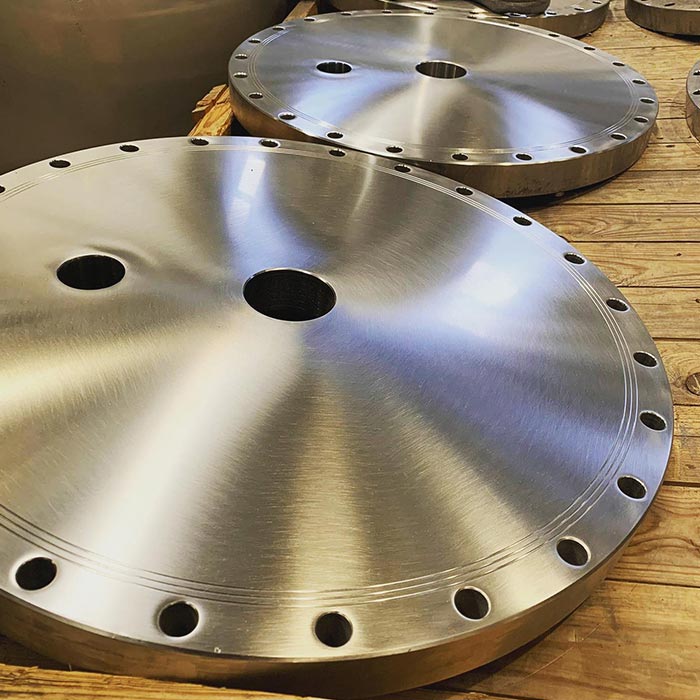

Finishing by polishing the metal to a mirror finish and satin-finishing

Polishing and satin finishing are metal surface finishes.

They have a decisive influence not only on the aesthetic aspect but also on the functional aspect of the material. Satin-finished or mirror-finished metal will behave differently to the actions of the external environment.

The surface is brought to the desired finish using manual, automatic or semi-automatic abrasives. Our experience enables us to carry out polishing and satin-finishing surface finishes on various types of metal. We carry out satin finishing and mirror polishing of stainless steel, aluminium satin finishing, as well as brass, iron, aluminium alloys and others.

We specialise in the finishing of machinery for the pharmaceutical, sterile, chemical and food industries.

We finish hoppers, agitators, washing chambers, sterilisers, vibrating screens, granulators, mills, separators, valves, dosers, glove-boxes, bins, tanks and various other components.

The differences between satin and mirror polishing of metals

There are several differences between these two types of metal cleaning processes.

The surface of satin-finished metal has an opaque appearance, whereas highly polished metal has a shiny, reflective surface. The satin finish also makes the metal surface less delicate.

The two finishes also differ in their ability to resist scratches, their surface porosity, their resistance to chemical aggression and their ability to allow dust and fluids to drain off.

High-gloss polishing of metals such as stainless steel, aluminium, copper and brass

Polishing is a system of grinding that makes the metal surface shiny and reflective. All surface imperfections such as extrusion marks, machining marks and other defects are removed.

The process achieves a very low roughness of the material, thanks to controlled abrasion of the surface using fine grain abrasive belts. In the final stage, steels and metals are processed using finishing abrasive paste (also in a version without animal fat) and cotton wheels. Microscopic irregularities in the material are filed down, giving the surface its typical shiny appearance.

The manual polishing process is achieved by working the metal with polishers and/or grinders.

Polishing can be requested with a precise surface roughness value expressed in micrometers.

Satin-finishing of stainless steel, aluminium, copper, brass surfaces

Satin finishing is a surface treatment that produces a smooth but matt finish on metal. This finish masks any surface defects in the material and at the same time eliminates those left by other machining operations.

Satin finishing is carried out with three-dimensional abrasives. It dulls the surface but maintains a low degree of roughness to prevent bacteria from settling in the grooves left by previous machining operations.

Satin-finishing can also be requested with a precise surface roughness value, expressed in micrometers.

Certifications and declarations of metal finishing

The roughness value required for polishing or satin-finishing metal can be certified by us by means of a so-called "swipe", i.e. a printout of the measured profile.

Our customers can request a statement, on our letterhead, containing all the identification data of the item concerned, the calibration data enabling the metrological traceability chain to be traced and the measurement specifications, in order to ensure traceability and compliance with requirements.